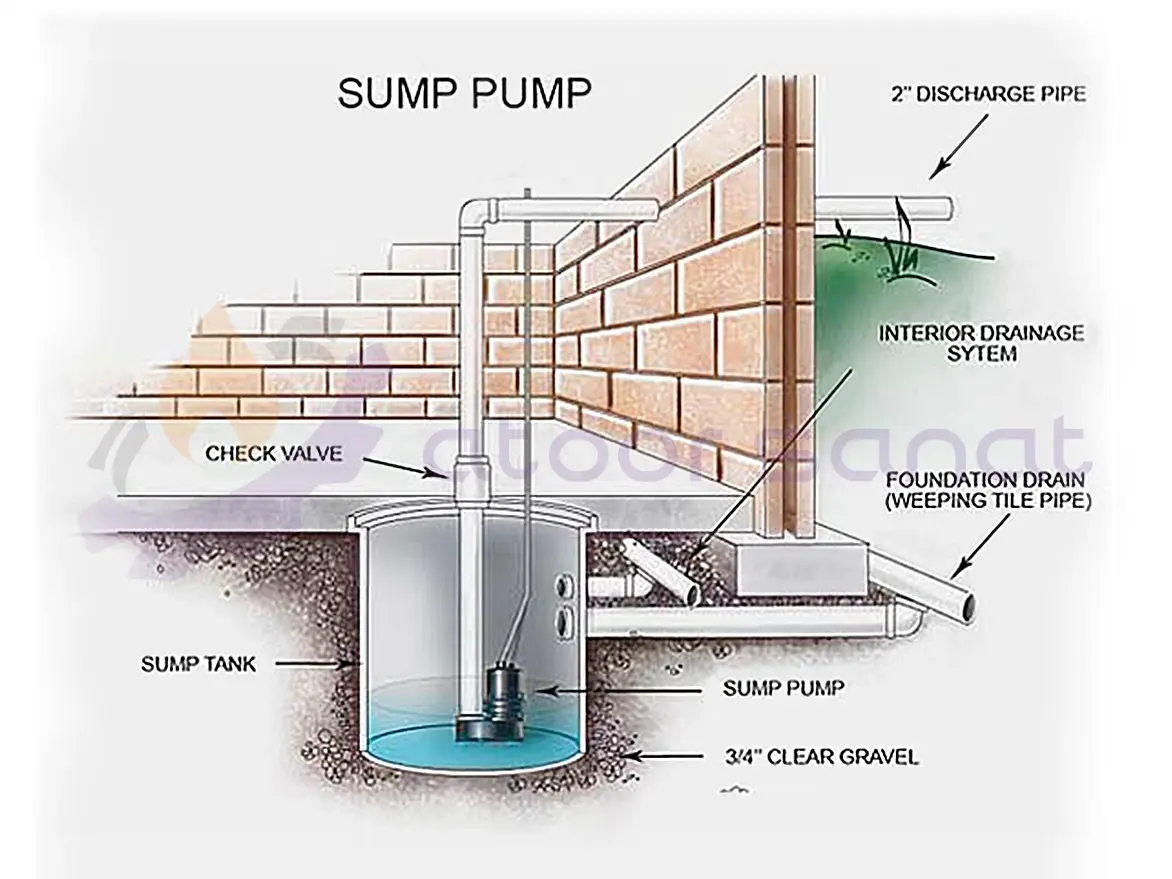

Typically installed at the lowest point of a building, a Sump pump is designed to prevent flooding after heavy rains or storms.

Pits or sumps below structures collect water. When the water level reaches a certain point, the pump automatically activates and pumps the water out of the lower part of the building. Inside the pump, an electric motor with a fan-like device drives the water through a pipe. Most of these pumps operate on electricity, but some are powered by batteries, which is advantageous during power outages caused by storms.

Most Sump pumps utilize a centrifugal pump to transfer liquid. When the electric motor starts, the impeller or rotor of the pump begins to spin. Due to centrifugal force and high-speed rotation, a low-pressure area is created in the center of the pump, causing the impeller to draw water from the bottom and direct it towards the sides of the pump. The water moves towards the low-pressure area, and the pump pushes the water into the discharge pipe.

The overall structure of this pump is very similar to a conventional centrifugal pump. The biggest difference is the absence of the diffuser section. In centrifugal pumps, the fluid at the outlet of the impeller has a very high velocity and low pressure. For many applications, this high speed and low pressure are not suitable, and some of the speed must be sacrificed to increase the pump’s pressure. For this purpose, vanes are used that are fixed around the impeller.

When the fluid strikes these vanes, it loses kinetic energy, and its pressure increases according to Bernoulli’s principle. In a Sump pump, depending on the application, an increase in pressure is not necessary, and in most cases, only a few meters of upward pumping are sufficient; therefore, the diffuser is removed in this pump.

There are two common designs for Sump pumps, both of which have a height of 75 to 90 centimeters. The first type is a floating pump that is submerged in water. The body of this pump prevents water from entering. The pump itself is located at the bottom, and the discharge pipe is at the top, with a flat plate or iron grate preventing any debris from entering.

The second type is a stationary pump. In this type, the pump is located outside the sump, and even when the sump is full of water, the pump is not submerged. The inlet pipe is also connected to the lowest point of the sump. This type of pump is noisier due to being located outside the water but is cheaper than the Sump type.

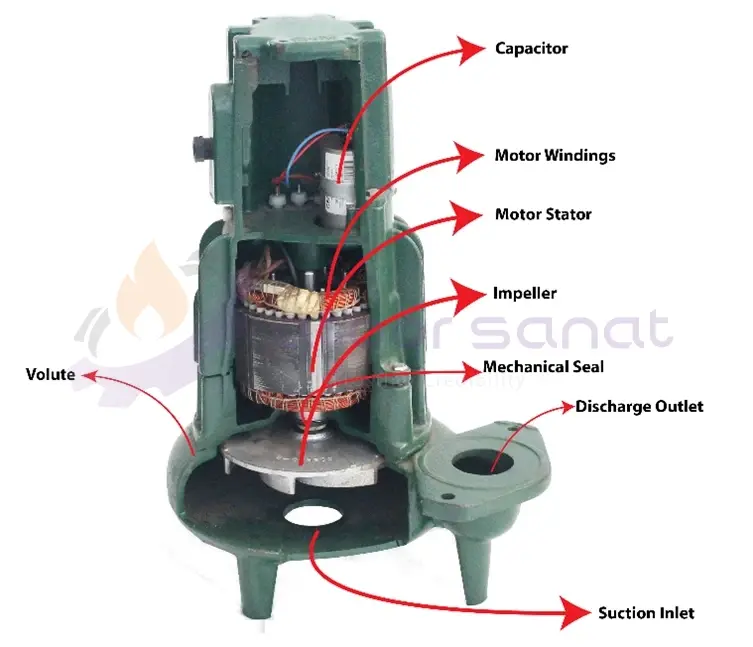

Components of a Sump Pump

Generally, a Sump pump consists of a casing and a motor. The casing is a curved box that acts as a diffuser in this pump. Inside the casing, there is a shaft that connects the electric motor to the impeller. There are four parts in the impeller:

- Eye: Where the fluid enters.

- Vanes: The part that drives the fluid.

- Channel or passage: The space between the vanes through which the fluid passes.

- Central hole: To which the shaft is connected.

The following image shows a type of impeller.

Impellers come in many different designs, and all of these designs can be single-suction or double-suction. In a single-suction impeller, the fluid enters the pump from only one side, while in a double-suction impeller, the fluid can enter the pump from two sides. The type of impeller is determined by the flow rate and pressure of the fluid.

The other main component of the pump is the electric motor, which converts electrical energy into mechanical energy. Unlike other pumps, the motor in this pump is directly connected to the impeller and is located inside the casing.

The sealing assembly of this pump has four parts. The first part is the primary seal, which is often made of silicon carbide, ceramic, or tungsten carbide. This part is located in the casing and in the rotating part and rotates with the impeller. The second part is the stationary seal. The third part consists of a spring that, along with the force of water pressure, completes the sealing process. The last part is the motor seal.

When the pump finishes its work and turns off, the water in the pipe flows back down. This return can interfere with the operation of the pump. In some Sump pumps, a check valve is installed at the outlet. With this valve installed, no water returns to the pump when it is turned off.