Circulator Pump

What is a Circulator Pump?

A circulator pump is a type of centrifugal pump used to circulate a fluid within a closed loop. It’s commonly used in residential applications to circulate hot water, ensuring that hot water taps, showers, and radiators receive hot water on demand. These systems continuously pump warm water from hot water pipes and return it to the system via cold water pipes.

A significant amount of energy is wasted in houses. A typical house has 125 feet of ¾ inch water pipe. This amount of pipe can hold 3.14 gallons of water at a time. If hot water is used ten times a day, 31 gallons of hot water will be wasted due to sitting in the pipes.

Over the course of a year, this adds up to 11,461 gallons, which is 9% of the average hot water usage for a typical house (131,000 gallons per year). This highlights the necessity of a circulator pump. In the case of water remaining in the pipes alone, the pump compensates for a large portion of this 9% loss.

Features:

- Country of Origin: Italy

- Maximum Pressure: 6 – 10 bar

- Body Material: Cast iron

- Maximum Fluid Temperature: -5 to 120 degrees Celsius

Features:

- Country of Origin: Denmark

- Maximum Pressure: 10 bar

- Body Material: Cast iron

- Impeller Material: Composite

Features:

- Country of Origin: Germany

- Maximum Pressure: 10 bar

- Body Material: Grey cast iron

- Impeller Material: Polypropylene

Features:

- Country of Origin: Japan

- Maximum Pressure: 1-2-4 bar

- Body Material: Cast iron, stainless steel 304

- Impeller Material: Technopolymer, stainless steel 304

Features:

- Country of Origin: China

- Maximum Head: 40-100 meters

- Body Material: Cast iron, grey cast iron

- Impeller Material: Cast iron, polypropylene

Features:

- Country of Origin: Italy

- Maximum Pressure: 6-14 bar

- Body Material: Cast iron

- Impeller Material: Technopolymer, cast iron

Features:

- Country of Origin: Iran

- Maximum Pressure: 2-16 bar

- Body Material: Cast iron GG25

- Impeller Material: Polypropylene

Features:

- Country of Origin: Iran

- Maximum Pressure: 2-16 bar

- Body Material: Cast iron GG25

- Impeller Material: Polypropylene

How a Circulator Pump Works

In standard houses with single-pipe systems without a circulator pump, the water, after passing through the heater, moves towards the faucet due to the pressure generated by the fluid itself as it enters the building. When the faucet is closed, the hot water remains in the pipe and cools down after a while. When the hot water faucet is opened again, the heater turns on and after a while, hot water reaches the faucet. By adding a circulator pump, the water is circulated through the cold pipes from the farthest point. The cold water returns to the heater, and no water is wasted while waiting. The energy consumption of a circulator pump is usually less than 25 watts.

To further reduce energy consumption, a circulator pump can be programmed for three different methods of supplying hot water. In the first method, a timer and thermostat are used to keep hot water in the pipes during times when it is needed, such as morning and evening. The user can set the timer for specific hours and use hot water at the set time. In the second method, the pump is activated manually or remotely. The third method, used in most systems, activates the pump through flow sensors, so that whenever water passes through the system, the pump is activated. In all these methods, temperature sensors in the hot water line and at the end of the pump inform the pump of the water heating to prevent pumping hot water into the cold line and the pump turns off automatically.

Technically, a circulator pump is not like other pumps. In all pumps used in various industrial, domestic, and agricultural applications, regardless of whether the pump is rotary or positive displacement, the outlet fluid has more pressure than the inlet fluid; however, this is not the case with a circulator pump. Of course, considering the purpose of this pump, which is only to circulate the fluid, this is not considered a weakness. The fluid that reaches the circulator pump is usually at the highest point and does not need to increase in head.

Circulator pumps are mostly single-stage. This pump works like any other centrifugal pump; the impeller, by rotating, provides the necessary speed for the fluid passing through the vanes. There are two types of circulator pumps, and their characteristics will be discussed below.

Vertical In-line Circulator Pump: The most common design of circulators in industrial and semi-industrial applications is the vertical in-line, which is named due to the vertical arrangement of the shaft. In this type, the electric motor is located above the pump, and the inlet and outlet are linearly embedded in the body. Some of these pumps are designed to be easily placed in a system’s piping. These pumps are mostly used for circulating hot and cold water in commercial buildings. The main advantage of the vertical in-line pump is the amount of space it saves compared to horizontal pumps. The second advantage is the simplification of piping. In conventional centrifugal pumps, the inlet and outlet directions differ by 90 degrees, but in this pump, the inlet and outlet are in the same direction. Therefore, in most commercial buildings, an in-line circulator pump can be easily installed like a valve in the piping. One disadvantage of these pumps is the application of the weight of the pump and electric motor to a small surface at the bottom of the body. The second disadvantage is the accumulation of leakage from the pump on the body, which instead of passing through the pump, remains stationary and causes corrosion. These pumps are of the wet type, meaning the electric motor and pump are in the same chamber and cannot be separated. A vertical in-line circulator pump requires a mechanical seal and can handle high flow rates. Their bodies are often made of cast iron, but in some cases, steel and brass are also used. The shaft is made of steel or ceramic, mounted on bearings, and extends into the water chamber.

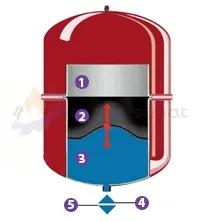

Dry Circulator Pump: Smaller versions of circulator pumps used in house heating systems and small commercial buildings have a centrifugal impeller inside the water and have a closed connection design that does not require a mechanical seal. This type of design is called dry because no other parts except the rotor come into contact with water. This type of arrangement is only applicable to low-power pumps, because at higher powers, the electric motor needs more cooling and must be placed inside a chamber through which water passes. The efficiency of these pumps is high (about 70%), which is why they are more commonly used. In this model of pump, flanges are more commonly used to connect to larger diameter pipes. In dry circulator pumps, the impeller chamber and electric motor can be easily separated; therefore, maintenance and repair are easier. When a circulator pump is used in a completely closed loop, i.e., a system where the fluid never experiences atmospheric pressure, such as a heating system, the system usually has an expansion tank. This tank is closed and connected to the pump suction line and has a diaphragm in the middle, with the upper part filled with air at a pressure higher than atmospheric pressure. When the fluid in the closed loop moves, it heats or cools, and this temperature change causes the volume of the fluid to increase or decrease. The air above the diaphragm in the expansion tank adjusts its volume to compensate for the expansion or contraction of the fluid. In the absence of an expansion tank, the pipes or other equipment may burst due to changes in fluid volume. The figure below shows an expansion tank where the volume of water, indicated by number 3, has increased due to an increase in temperature, and the volume of air, indicated by number 2, has decreased.

Components of a Circulator Pump

Dry and wet circulator pumps differ in some of their components. Because the sealing system is eliminated in the dry type and the electric motor is separate from the water chamber, the dry pump has a simpler design. Below, we will examine the components of both types.

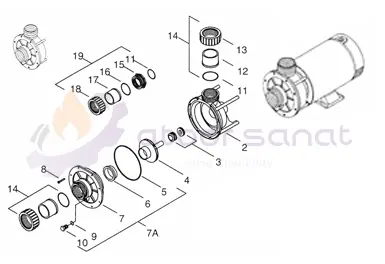

Components of a Dry Circulator Pump:

- Screws

- Cover plate

- Chamber O-ring

- Impeller

- Shaft seal

- Housing

- Pump half coupling

- Coupling O-ring

- Electric motor

- Motor protective cover

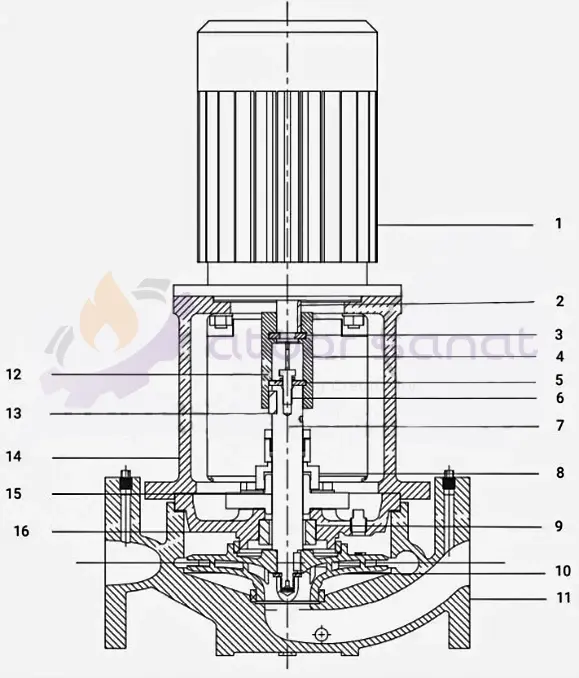

Components of a Wet Circulator Pump:

- Electric motor

- Shaft collar

- Pump shaft

- Shaft collar

- Connecting ring

- Hex nut

- Pump shaft

- Mechanical seal

- Bush sleeve

- Impeller

- Body

- Spring washer

- Shaft collar

- Motor mount

- Split coupling

- Gland

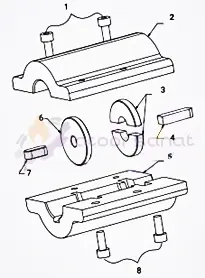

Components of the Split Coupling System in a Wet Circulator Pump:

- Socket screws

- Upper half

- Washer

- Pin

- Lower half

- Connecting ring

- Pin

- Socket screws

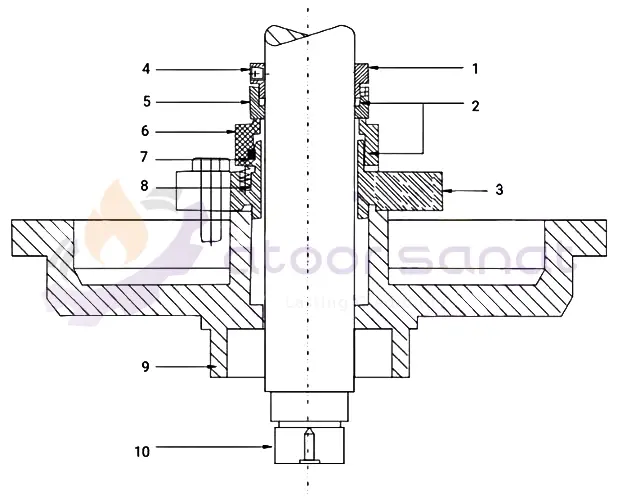

Components of the Sealing System in a Wet Circulator Pump:

- Seal ring

- O-ring

- Gland plate

- Adjusting screws

- Sealing ring

- Connecting ring

- O-ring

- Spring

- Gland

- Shaft